The story behind the Rocket success

Which go-kart engine has been produced in the most copies? Yamaha? Rotax? Any Italian engine? No, the answer is that the engine that has not only been produced in the most numbers but has also been in production and use for the most years, that engine is called the Raket and is still going strong. Read here about the history of the engine.

Background

At the end of the twentieth century, the Italian Komet, Saetta and Parilla engines dominated. New engines appeared every year, always with higher power, which was usually produced at higher and higher revs. They were exciting engines, but they were expensive and sometimes they were not reliable. As a result, karting became more and more an expensive elite sport, as there was no class for young drivers or drivers who wanted to race mostly for fun and could not afford two or three engines per season. By the way, at that time, the sport was not called go-karting, which was the original American term, but Formula K.

In the mid-1960s, attempts were made to introduce classes that could become more popular by allowing people to race with simpler, cheaper and more reliable engines. One such effort was called Class A Popular, and some rebuilt chainsaw engines were homologated for the class, including an older 90cc engine from Partner. Common to the engines in the class was that they were equipped with a reed valve. This ingenious invention works very well with a diaphragm carburettor, and normally produces engines with good torque at low and medium rpm. The reed also becomes a rev limiter quite automatically. However, Class A popularity was not as popular as the Formula K committee had hoped, at least not until converted Italian engines appeared that had been fitted with the reed. Then, of course, the situation became that those racing Italian could race eights around those who were harping around with a Partner or Husqvarna engine. And that was the end of the fun. The Formula K committee was once again able to state that it was not so easy to find a class where a fat wallet could not buy you a place on the podium.

So why didn't someone come up with the good idea of making a simple, cheap and reliable go-kart engine that also looked tough and didn't look like a chainsaw had been dropped behind the back of the kart? The answer is that certain components such as pistons, cylinders and crankshafts have to be produced in very large series in order to get down to acceptable unit prices. The experiments that had been done with chainsaw engines were worthwhile, because they used components that were in plentiful supply, and saw engines are normally very reliable. The mistake that had been made was that too much of the chainsaw had been retained, so that the real go-kart feeling did not want to emerge.

Background with Partner

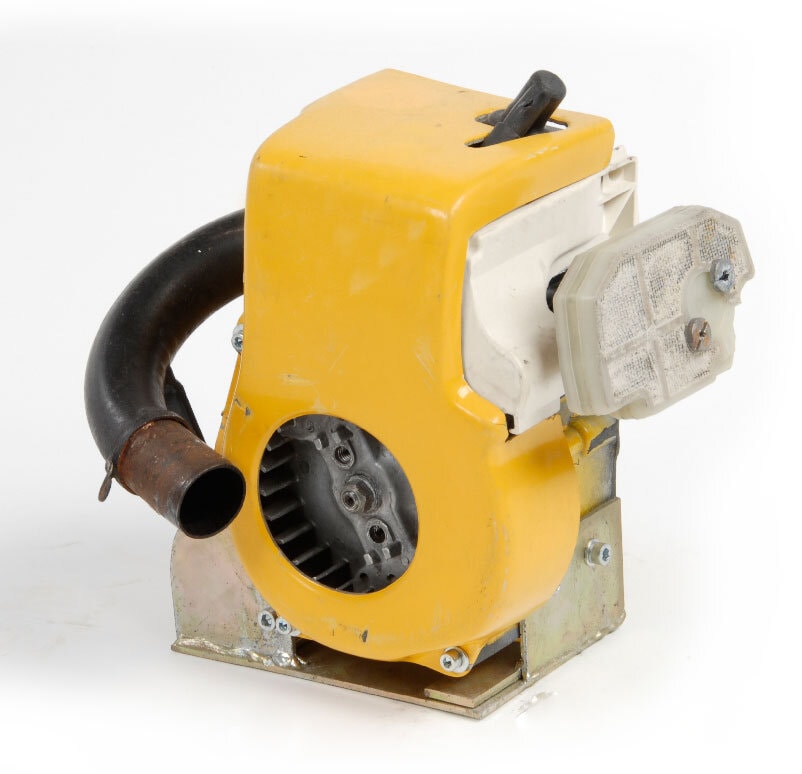

In the early seventies, a development team at Partner in Stockholm was working on a series of chainsaws with 85 cm3 and 100 cm3 cylinder capacity. That's quite a lot in chainsaw circles, and the saws were intended for exotic markets where they worked with the really big bamboo trees, for example in South America. Production-wise, the two models would be quite similar as far as piston and cylinder. In 1971 and 1972, these engines were run in brake bench to optimise performance and reliability. The brake-bench engines consisted of a simple sand-cast crankcase, a simple fan shroud but otherwise with perfectly correct components such as crankcase, cylinder and ignition system. By the end of 1972, the tests were completed and Partner ordered production tooling for the new saws. A young man who had been working in the lab quit at the same time and he asked if he could take some of the test engines as a souvenir, as they were just lying in a box and cluttering up.

Creating a youth class

The following year, Leif Radne and former Partner employee Bo Sörensson met and the idea of a new engine for a youth class came up. Then the test engines came out, and Leif Radne turned them over and over and scratched his head. Sand-cast crankcases and fan cowls, that could perhaps be arranged. Buy the piston, cylinder, ignition system and carburettor from Partner. Hm, Hm maybe - we'll have to think about it. And as they say in such contexts, the rest is history. Back home on Violabergsvägen in Vendelsö, Leif sat down and redesigned some parts, such as the crankcase, so that it would be suitable for go-karting. A first test series was produced, half with 85 cm3 cylinder and half with 100 cm3. A test run on the ÖsWe-ring showed that Leif was on the right track. Not only did the engines, initially called Partner RS85 and Partner RS100, behave well, they looked like go-kart engines, they sounded like go-kart engines and who knows if they even smelled like go-kart engines.

New Class

Leif took the engines in a box and went up to the Motorsport Federation and showed the new engines to the Formula K committee. The result was two new classes, one for each cylinder volume. Other engines with the same background also made some lame attempts, but right from the start the engines from Radne Motor came to dominate. It turned out that the 85 cm3 engine was almost indestructible, while the 100 cm3 engine had enormous problems with cooling. Therefore, after a few years, the 100 cm3 version was discontinued, and the 85 cm3 engine was homologated for the Mini and Micro classes.

Longevity

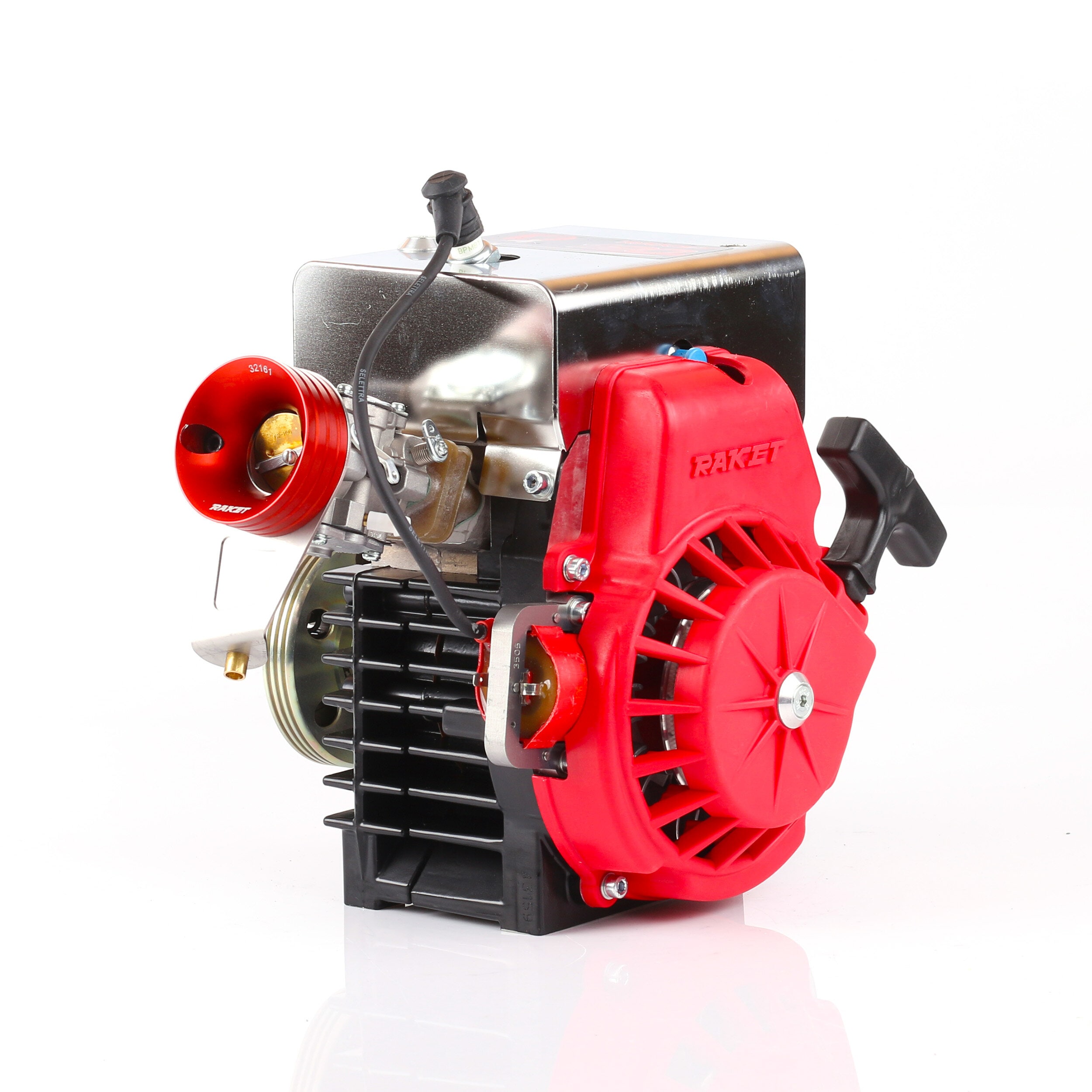

What is it they say about the original Volkswagen, well that although the looks were largely retained, there were no parts from the original Folkan that would fit in the later model years. With the engines from Radne Motor, it's almost exactly the opposite. Certainly, a lot has changed. The sand-cast crankcases are now coke-cast, the fan shroud is plastic and, by the way, the engine is no longer called Partner but Raket. But, if you have a cylinder from 1974, or a carburetor or a crankcase, well then they still fit in a brand new 2014 engine. This has been an important principle for Radne Motor, not to change what is already good. If you have bought an engine one year, you should be able to ride with the same stuff for several years and not have to change to a new model year. This will also be the benchmark for the future. As long as Radne Motor can buy the basic components, the Rocket motors will remain largely unchanged, though constantly improved.

Over fifty thousand engines

Since the first tentative start in 1974 until this year, Radne Motor has produced more than 50,000 Rocket motors. Today they are used in youth classes like Mini and Micro in many places on our earth. From Radne's facility in Stockholm, Raket motors are shipped to several European countries, but also to lucky riders in China and far away in New Zealand. By the way, Raket motors are not only used for racing, there are models for hobby karting as well as for those who don't want to race, but like to be able to drive a kart once in a while. A strongly increasing use of rocket engines is for flying. Well that's for sure. For the very lightest machines like Ultra Light Aircrafts and hang gliders and paragliders, Rocket Engines are an engine to be reckoned with. Then they are equipped with a propeller, either directly on the crankshaft or via a gearbox. Next time you hear something buzzing in the air look up there's a good chance it's a Rocket on a paramotor.

Where are the Radne - Raket engines made?

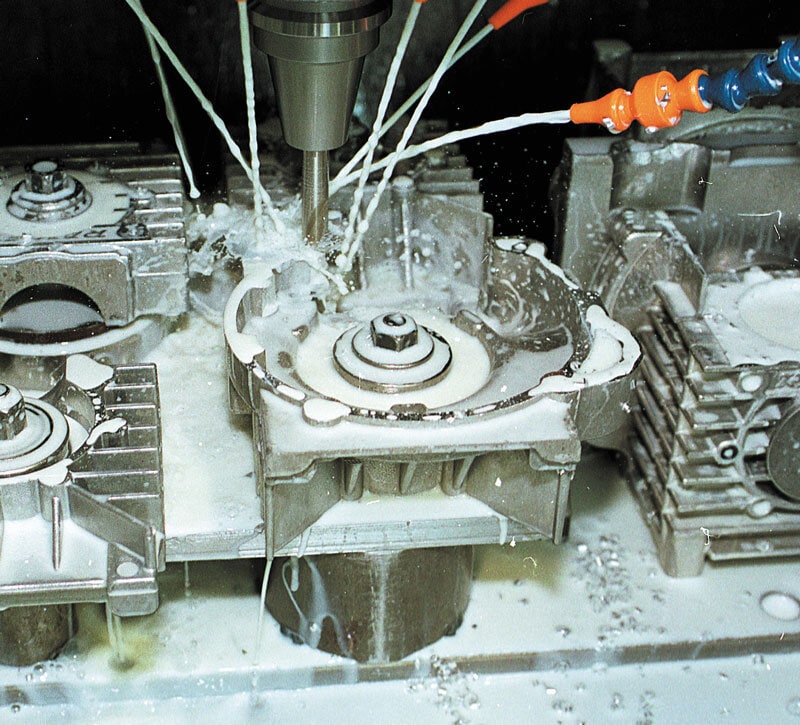

Do you want to know how and where Raket engines are made today? Well, then you are welcome to visit the factory in Handen. The crankcase is made in Sweden, and the piston and cylinder are made by the German company Mahle.

The crankcases are cast in Denmark, the carburettors come from Ireland. All these components are purchased, checked and stocked at Radne Motor. This is also where the final assembly and final inspection takes place. Production is around 30 engines a week, including all the different types.

There is a persistent rumour that there are specially selected engines that are a notch better than a normal engine. Anyone who has seen the stock of hundreds of cylinders, hundreds of crankcases and so on, and seen that they are all checked against the same templates and that deviations are within extremely tight tolerances, will understand that it would be a hopeless task to find the particular combination of all the components that could give any driver an advantage on the track. Especially when you consider the enormously greater impact of a correctly set up carburettor. And finally, the biggest difference between the various vehicles is to be found in the person holding the steering wheel.

The founder himself, Leif Radne, who has more than fifty years of experience in the karting industry, defines a good Rocket engine as the engine that gives all drivers the same conditions - then it just depends on the driver and to some extent on the mechanic.

You are welcome to call us at any time to talk about our engines